Winter creates a unique set of challenges for commercial HVAC systems across North America. Long heating seasons, tightly sealed buildings, and rising expectations for indoor air quality push ventilation systems to operate at near-constant load. Since the pandemic, guidelines and recommendations such as the adoption of MERV 13 filters have become increasingly common in offices, schools, and public buildings. While higher filtration improves indoor air quality, it also introduces a critical trade-off. Traditional MERV 13 filters often come with higher airflow resistance, which can significantly increase fan energy consumption during the winter months. This raises an important question for building owners and facility managers: how can indoor air quality be improved without driving energy costs even higher?

Pressure drop refers to the difference in air pressure measured before and after air passes through a filter. In HVAC systems, this resistance is an unavoidable part of filtration, but it has a direct impact on how much energy a system consumes. The higher the pressure drop, the harder the fan or blower motor must work to maintain the required airflow, which increases electrical load and operating costs.

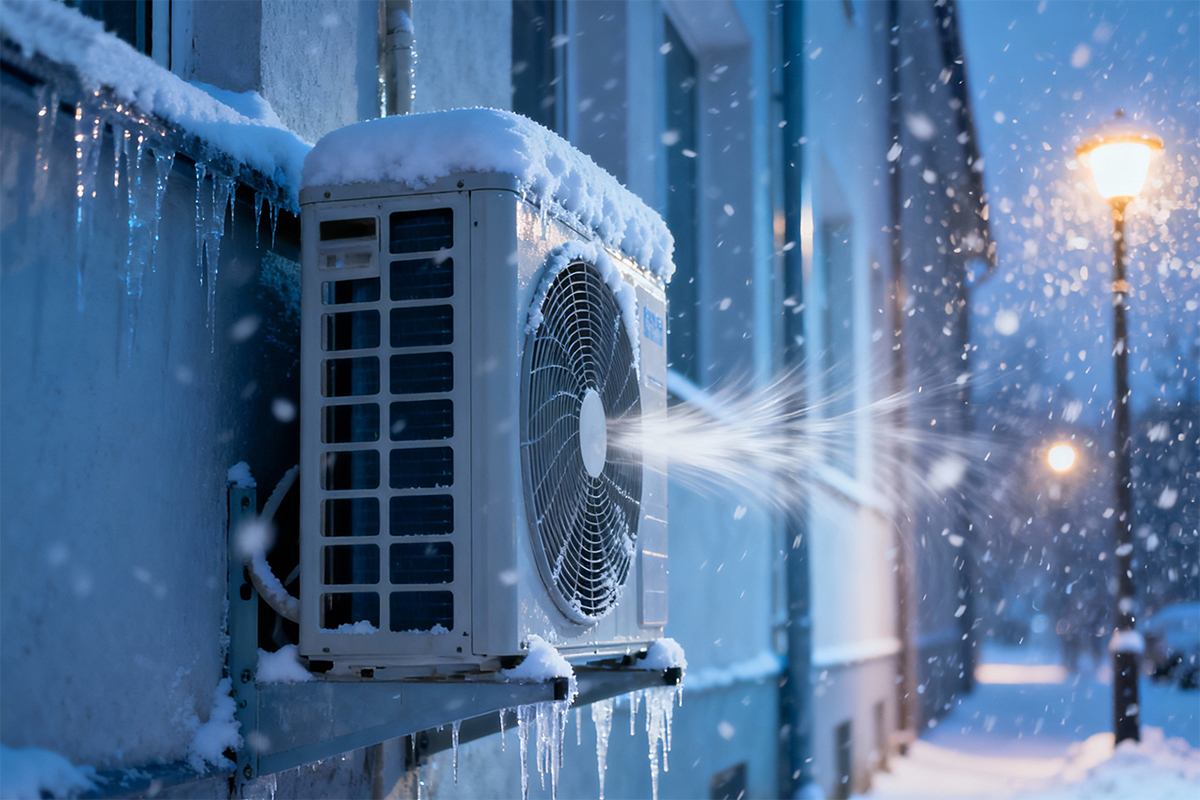

During winter, the effect of pressure drop is amplified. Unlike cooling systems that cycle on and off during warmer months, heating systems in commercial buildings often operate continuously to maintain stable indoor temperatures and prevent issues such as cold spots or frozen piping. Fans may run around the clock, meaning even small increases in resistance translate into higher energy consumption over time. A reduction of just a few Pascals in pressure drop may seem minor on paper, but across an entire heating season, it can represent a significant difference in total energy use.

Cold air also behaves differently than warm air. Increased air density during winter adds to the overall system resistance, further magnifying the impact of restrictive filters. In this context, selecting filters with lower pressure drop is not merely an efficiency improvement, but a practical strategy to control energy demand during the most energy-intensive months of the year.

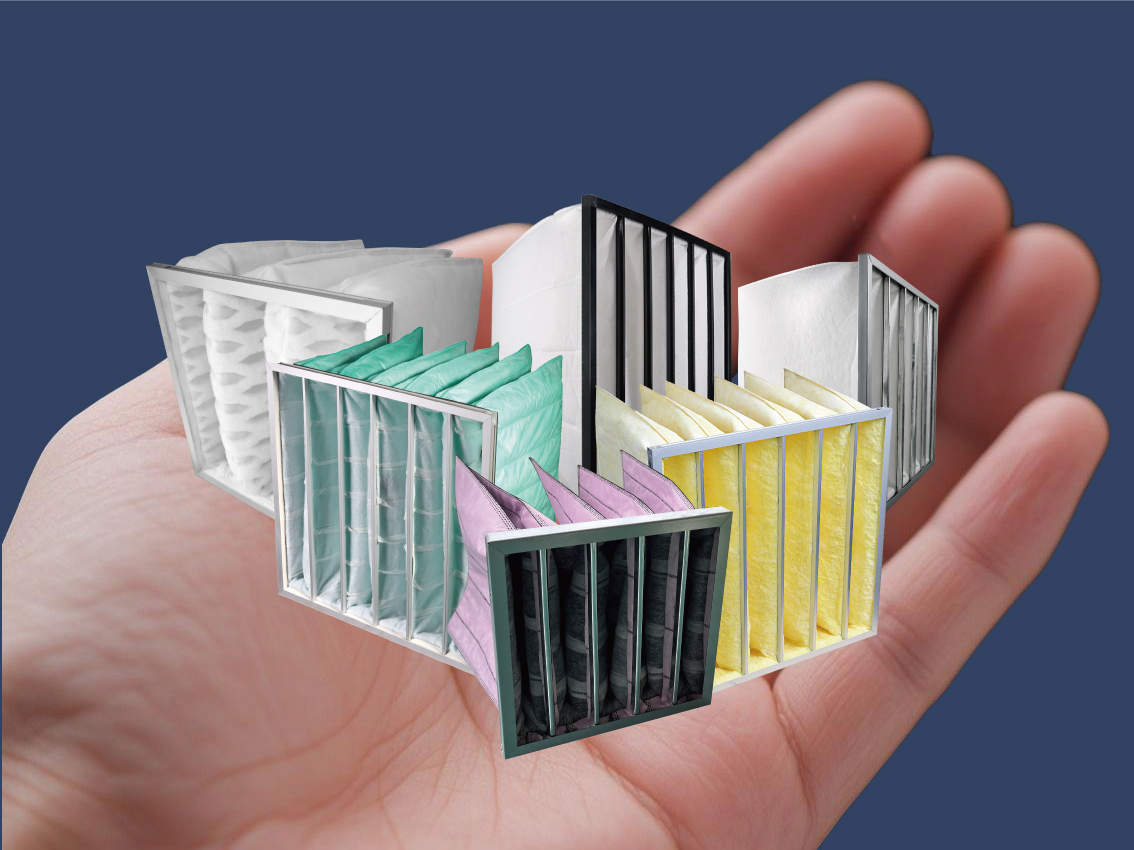

Low pressure drop MERV 13 filters offer a balanced solution for commercial buildings that must meet indoor air quality requirements while managing winter energy costs. From an operational perspective, their advantages extend beyond filtration efficiency and directly affect system performance, maintenance planning, and long-term cost control.

Fan energy consumption is closely tied to airflow resistance within the HVAC system. When pressure drop is reduced, fans require less power to deliver the same volume of air. Over the course of a winter heating season, this reduction can translate into meaningful energy savings, especially in buildings where ventilation systems operate continuously.

While low pressure drop MERV 13 filters may carry a slightly higher initial purchase cost, the reduction in electrical demand often offsets this difference within a short period. In many commercial facilities, the savings accumulated over several months of winter operation can exceed the price difference between standard and optimized filter designs.

High pressure drop places additional strain on fan motors and other HVAC components. During winter, when systems operate under sustained load, this strain can accelerate wear and increase the risk of overheating or mechanical failure. Filters designed to maintain low resistance help protect these components by allowing airflow to move more freely.

In addition, many low pressure drop filters are engineered with higher dust-holding capacity. This allows them to perform consistently over longer service intervals, reducing the frequency of filter replacements and lowering maintenance labor requirements during peak heating seasons.

Achieving high filtration efficiency does not have to come at the expense of airflow performance. Low pressure drop MERV 13 filters are capable of capturing a high percentage of fine particles, including PM2.5 and other airborne contaminants, while maintaining stable system operation.

This balance is particularly important in commercial environments where regulatory expectations for indoor air quality continue to rise. By maintaining compliance without increasing system resistance, these filters support healthier indoor environments while keeping energy use under control.

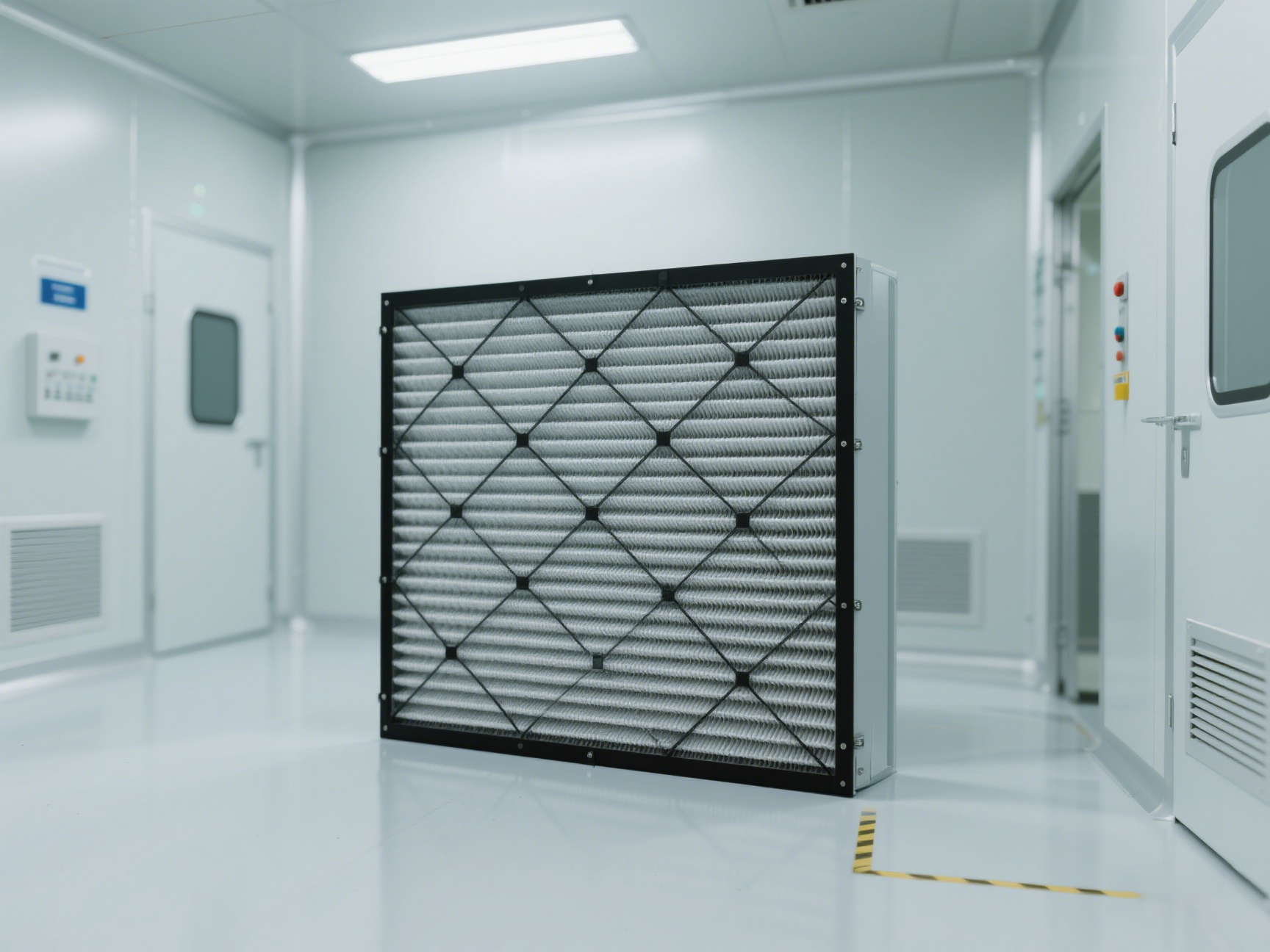

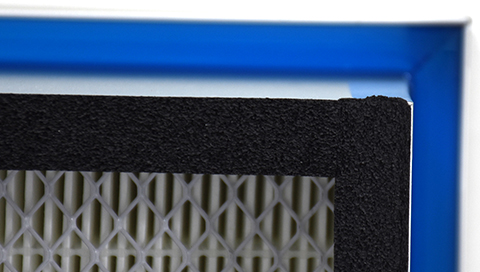

From a manufacturing standpoint, achieving low pressure drop in a MERV 13 filter is not about chasing a single technology. It is about balancing multiple constraints that HVAC systems face in real operating conditions, especially during winter.

One common misconception in the market is that simply using denser media will improve filtration performance. In reality, overly dense media often creates excessive resistance, forcing fans to work harder and negating any theoretical gains in efficiency. Over the years, manufacturers have learned that media structure matters more than thickness alone.

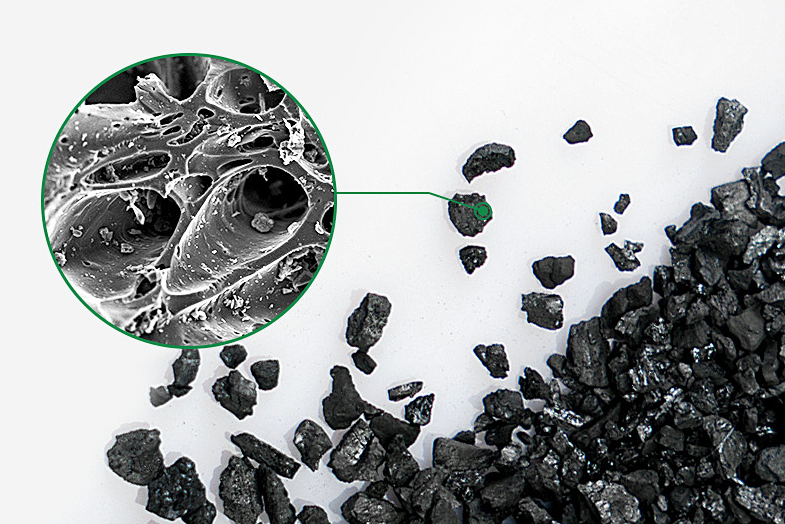

Modern low pressure drop MERV 13 filters rely on carefully engineered synthetic media with a gradient density structure. This approach allows larger particles to be captured on the upstream side, while finer particles are trapped deeper within the media. As a result, airflow remains stable even as dust loading increases over time, which is especially important during long winter operating cycles.

Equally important is how the filter media is shaped and supported. Increasing effective surface area through optimized pleat geometry distributes airflow more evenly across the filter. Poorly designed pleats can collapse or block airflow paths under continuous winter operation, while well-engineered pleat spacing maintains open air channels and prevents localized pressure spikes.

Another factor often overlooked is the role of electrostatic enhancement. Instead of relying solely on mechanical interception, electrostatic attraction helps capture fine particles such as PM2.5 with less physical obstruction. This allows the filter to maintain high efficiency without sacrificing airflow, even as environmental conditions fluctuate.

Ultimately, low pressure drop performance is not achieved through a single feature, but through a system-level approach. Material selection, structural design, and real-world operating feedback all play a role. Filters that perform well on paper but fail to account for continuous winter operation often underdeliver in commercial buildings.