With the advancement of production, static electricity has gained increasing recognition. The application of technologies such as electrostatic flocking, electrostatic copying, and electrostatic spraying has brought numerous benefits to humanity. However, fires and explosions caused by static electricity have also inflicted considerable harm. Currently, anti-static measures have become a critical topic in modern industrial production safety technology.

Since most coatings use various flammable solvents as diluents, the static electricity generated during spraying can easily ignite or detonate the vapors of these solvents upon discharge. Therefore, preventing and mitigating the hazards of static electricity in coating spraying is a critical issue that cannot be overlooked.

The paints and organic solvents such as xylene and butyl acetate used in spray booths are highly flammable. Their volatile gases can form explosive mixtures when mixed with air. Upon reaching the lower explosive limit, these mixtures will ignite upon contact with an ignition source. During the spraying process, paint droplets, airflow, and equipment friction readily generate static electricity. When static accumulates to a certain voltage, it discharges as sparks. The energy of these sparks is sufficient to ignite or detonate surrounding flammable gas mixtures, making static electricity one of the primary causes of fires and explosions in spray booths.

Electrostatic charges attract airborne contaminants such as dust, fibers, and impurities. When these contaminants adhere to the surface of the workpiece, they cause defects like particles, pinholes, and orange peel in the coating. These flaws severely compromise the coating's appearance, adhesion, and corrosion resistance. For high-end manufacturing applications like automotive bodies and electronic enclosures, such defects may result in product scrap and increased production costs.

In fact, this is not the correct interpretation. Ventilation equipment does not absolutely prohibit static electricity; rather, it must strictly control the generation and accumulation of static electricity to prevent it from reaching dangerous thresholds.

To avoid electrostatic risks, ventilation equipment must meet the following requirements:

Use conductive or antistatic materials: Components such as ventilation ducts, fans, and filters should prioritize materials with good conductive properties or antistatic materials.

Grounding Measures: All ventilation equipment capable of generating static electricity must be reliably grounded to ensure that static electricity can be safely dissipated into the earth through the grounding system.

Preventing Static Electricity Buildup: Uniform and smooth airflow distribution within ventilation systems is essential to avoid localized high-velocity airflow that can cause static accumulation. Regularly clean accumulated dust and paint mist from ventilation ducts to prevent impurities from adhering and increasing static adsorption.

Function: Intercepts ≥5μm large particulate contaminants in fresh or return air within spray booths, including paint mist clumps, coating residues, external dust, and fibrous impurities. Protects subsequent medium-efficiency and high-efficiency filters from rapid clogging, serving as the first line of defense in ventilation systems.

Applicable Product Types:

Panel/Pleated Primary Filters:

Constructed from non-woven fabric, metal mesh, or similar materials, achieving filtration efficiency of G3 to G4. These filters offer high dust-holding capacity and low resistance (initial pressure drop ≤50Pa), making them suitable for installation at workshop fresh air inlets or main return air ducts to intercept large dust particles and paint residue.

Primary Filter Cotton:

Such as the RT-C22 series and RT-LC20 series. These utilize a synthetic fiber gradient structure (low density on the air-inflow side, high density on the air-outflow side), covering filtration efficiency from G2 to F5 grades. Characterized by high dust-holding capacity and low resistance, they are washable and reusable, widely applied in panel or bag filters, and suitable for pre-filtration in general industrial spray booths.

Core Function: Filters residual fine particulate contaminants such as paint mist and dust particles measuring 1–5μm after primary filtration, further purifying the air and reducing the load on high-efficiency filters. Serves as the second line of defense in ventilation systems.

Applicable Product Types:

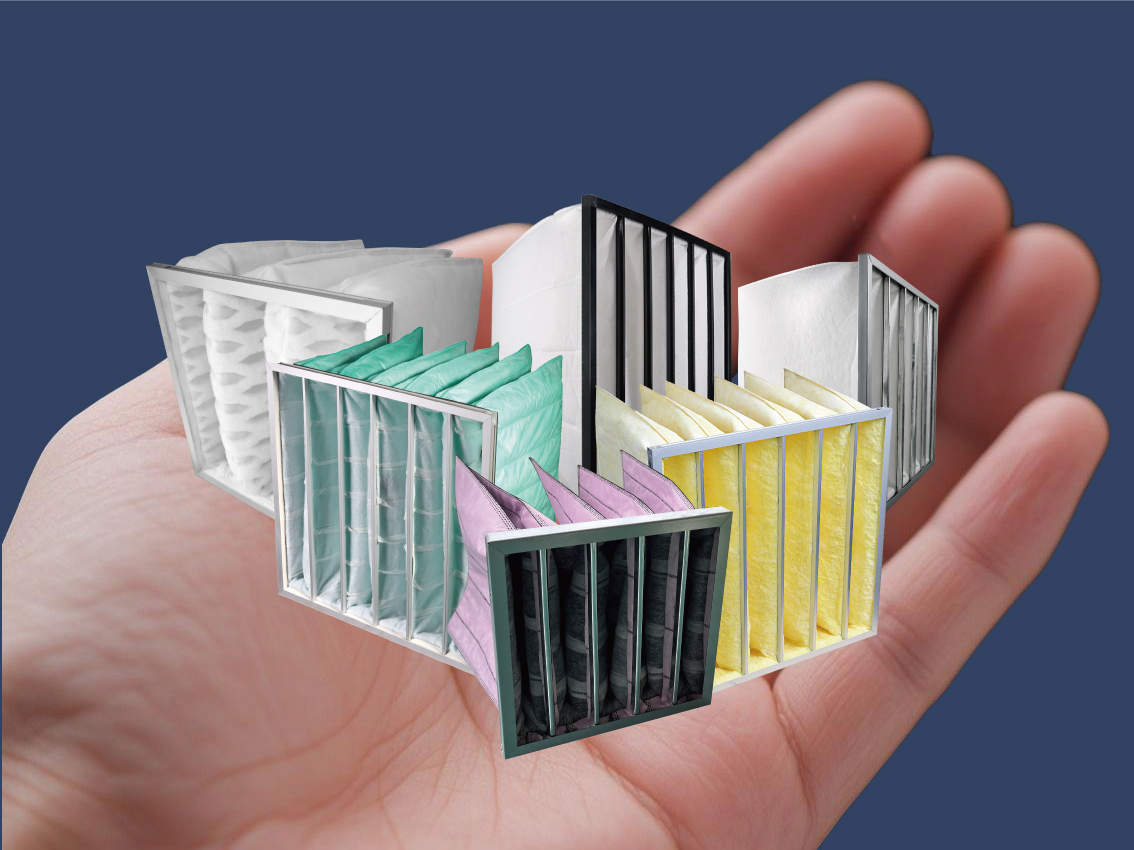

Medium Efficiency Bag Filters: Utilizing ultra-fine glass fiber or synthetic fiber media, the bag design increases filtration area. Available in 3- to 12-bag configurations, they offer high dust-holding capacity with filtration efficiency reaching F5 to F9 levels. Suitable for installation after primary filters.

Paint Mist Specialized Filters: Examples include DPA paint mist filters and V-shaped pleated paper filters. Featuring multi-layer pleated designs that increase dust-holding capacity, these filters target viscous paint mist generated during spraying—such as oily paint resin particles—offering high capture rates and easy replacement. They can be directly installed at the exhaust outlet of spray booths to prevent paint mist from entering ventilation ducts and contaminating other equipment.

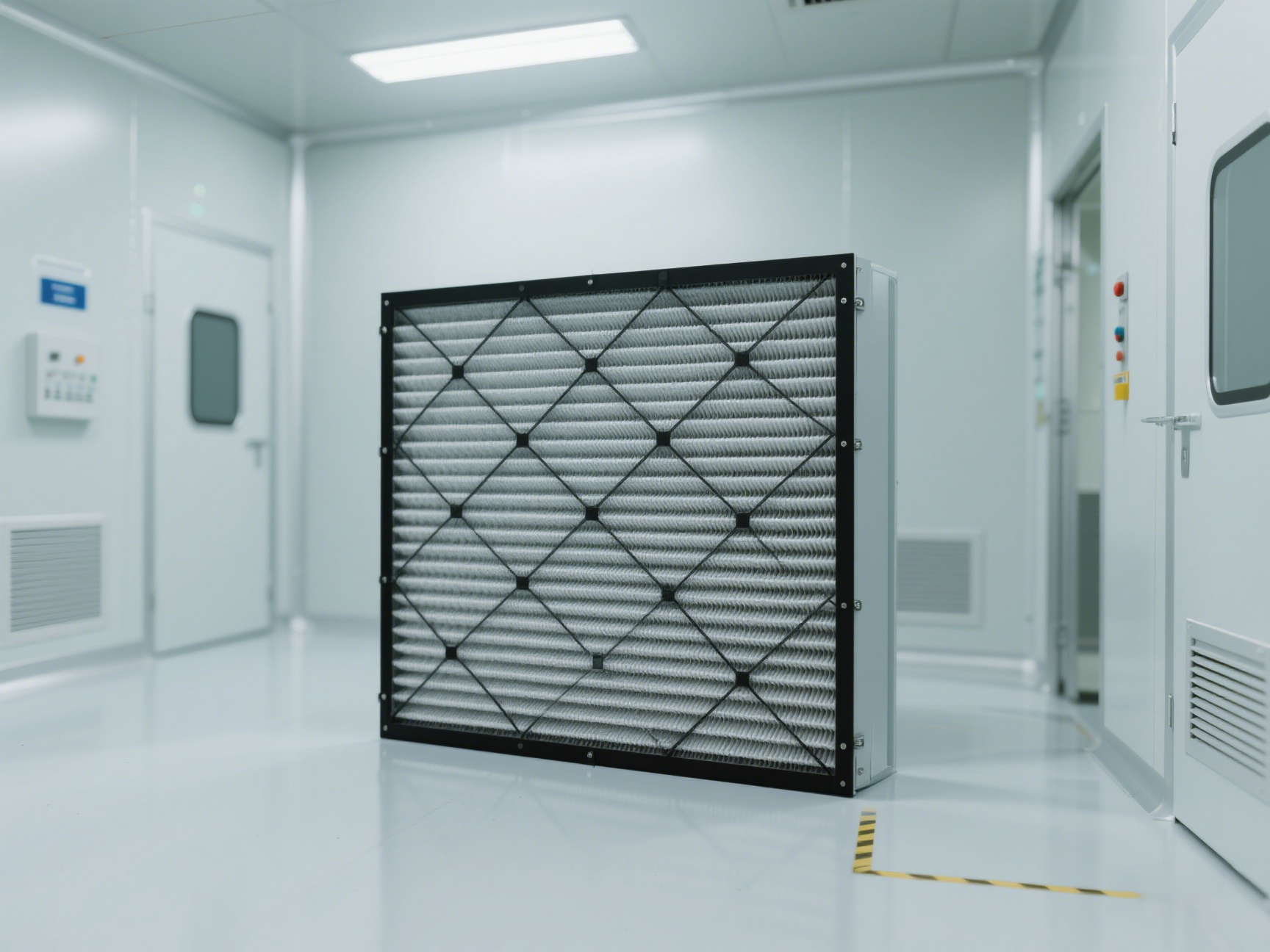

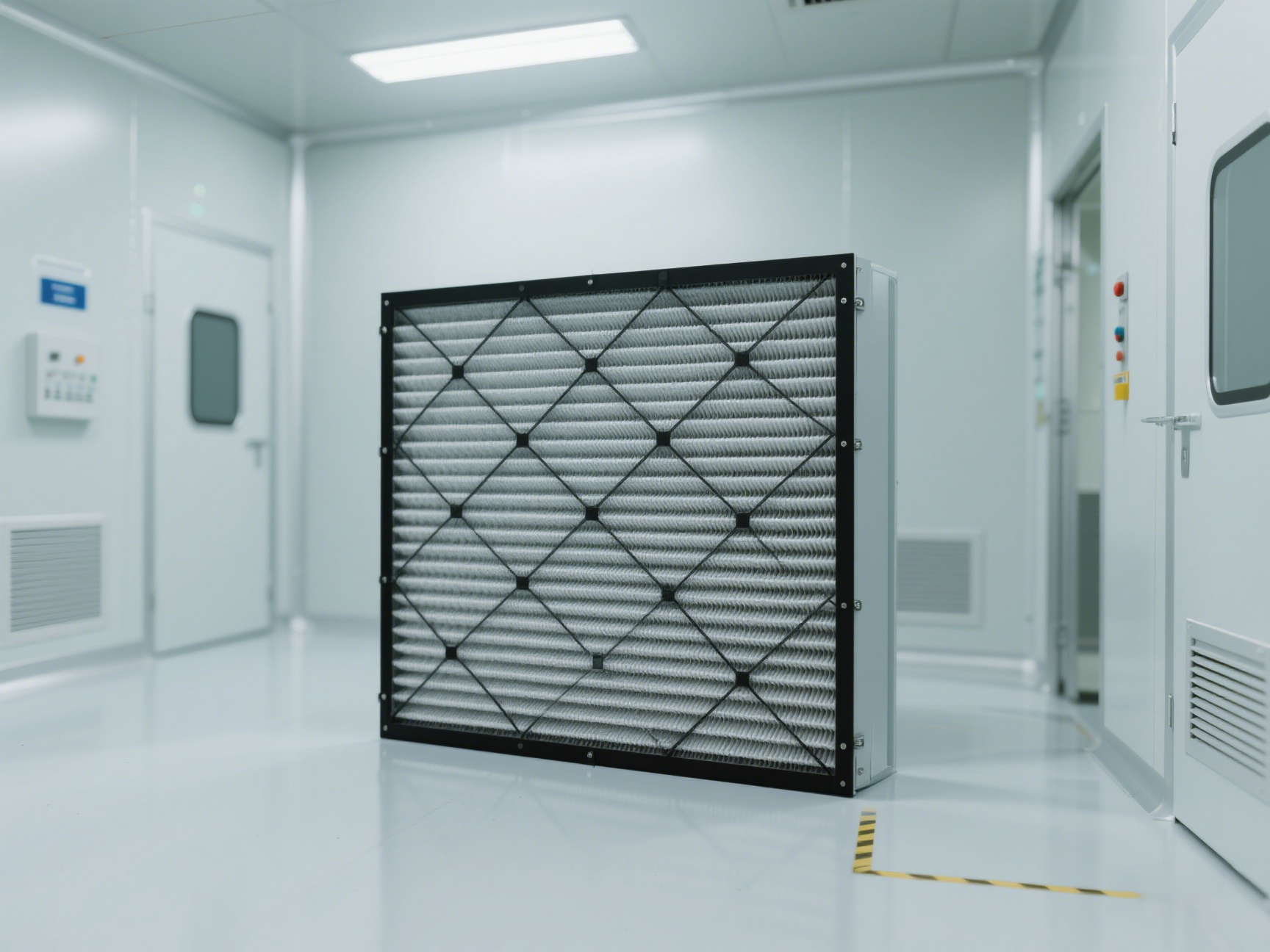

Core Function: Filters ultra-fine particles smaller than 0.3μm remaining after medium-efficiency filtration (e.g., mist-like paint mist, ultrafine dust, toner aerosols), meeting cleanliness requirements for precision spraying applications (e.g., automotive topcoats, electronic enclosures). Serves as the ventilation system's “last line of defense.”

Applicable Product Types:

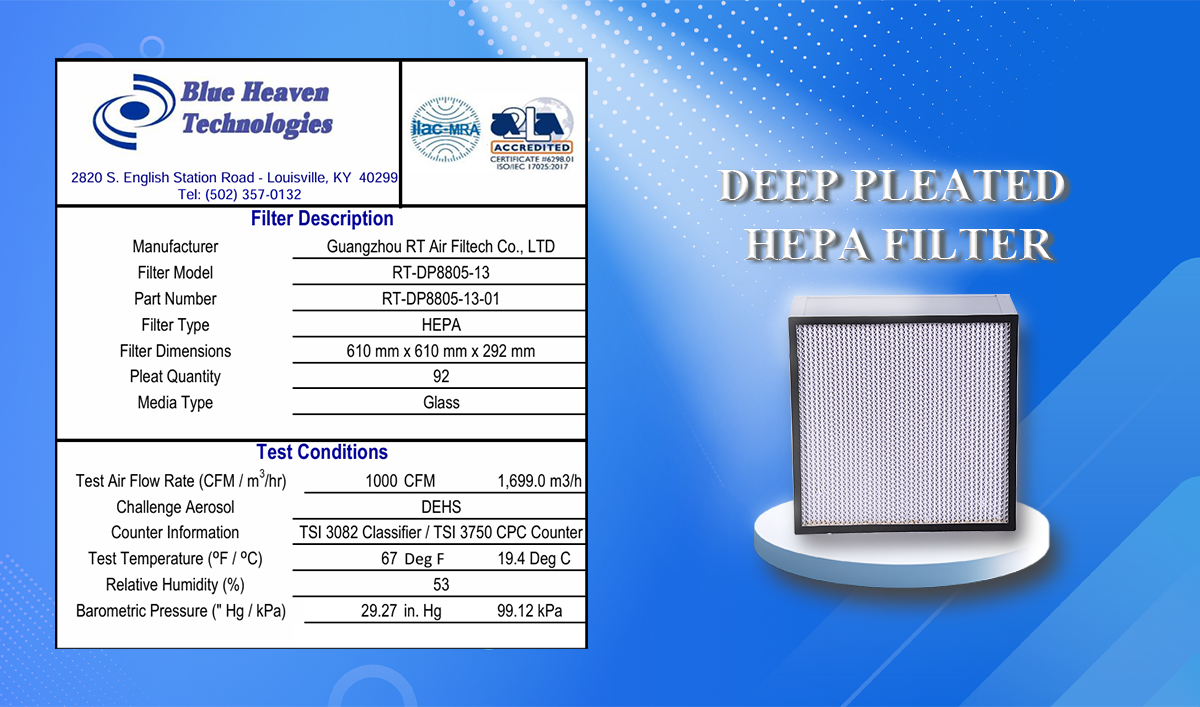

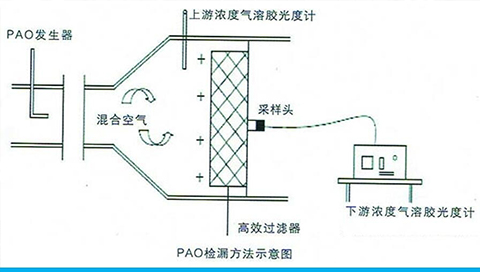

High-Efficiency Particulate Air (HEPA) Filter: Utilizes glass fiber filter paper with a pleatless design, achieving filtration efficiency ≥ 99.97%@0.3μm. Coverage spans H13 to H14 filtration grades. Suitable for installation at the end of supply ducts or cleanroom exhaust outlets to ensure air entering spray areas meets Class 1000 to Class 100 cleanliness standards.

Typically, spray booths do not necessarily require HEPA filters. Moreover, a HEPA filter has a very long service life. HEPA filters are only suitable for specific scenarios; you can refer to your spray booth cleanliness standards when making procurement decisions.

RT Air Filtech Professional Consultation: info@rtfiltech.com

Core Function: Provides a more efficient interception solution for high-concentration, viscous paint mist generated during spraying processes, reducing the burden on subsequent filters and extending the service life of the entire filtration system.

Applicable Product Types:

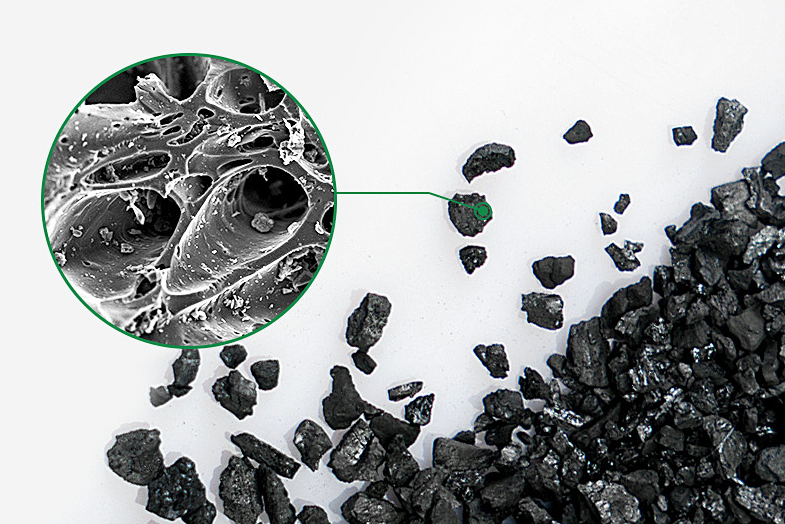

Paint Mist Felt: Utilizes loose-pile glass fiber felt (PA-50/PA-100) with a progressively denser structure (green on air inlet side, white on air outlet side). Features high capture efficiency, moisture resistance, low compressibility, and dimensional stability. Suitable for installation at the end of spray booths or in heat recovery systems to intercept viscous paint mist.

Honeycomb Paint Mist Filter: Utilizes specialized paper honeycomb filter media with fire-resistant and anti-static properties. Offers 30% lower air resistance than traditional filters and high dust-holding capacity. Achieves over 92% paint mist capture efficiency. Suitable for localized filtration in dry spray booths, effectively handling high-concentration paint mist. Ideal for small-batch production laboratories or mobile spray equipment.

For diverse ventilation scenarios such as paint booths, cleanrooms, and central air conditioning systems, we offer tailored product solutions: For paint booth ventilation, we provide specialized paint mist filters that effectively capture viscous paint mist to prevent duct blockages; For cleanrooms, we provide high-efficiency filters (such as H13~H14 grade non-pleated filters) meeting Class 100~10000 cleanliness requirements. For central air conditioning systems, we offer a three-stage filtration combination (pre-filter + medium-efficiency filter + high-efficiency filter) that efficiently removes airborne particulates and odors. Regardless of the ventilation application required, we deliver one-stop procurement services to ensure stable and efficient system operation.